Featuring High Reliability and Exceptional Thermal Stability

Manufactured exclusively for high temperature applications, EXOTHERM FEP (Fluorinated Ethylene Propylene) insulated wires exhibit excellent thermal, physical, and electrical properties. They are resistant to cold flow or cut through, ultraviolet radiation, and electro mechanical stress cracking. Moreover, they are inert to most harsh chemicals, oils, and solvents. Due to these superior attributes, FEP insulated wires are largely procured for demanding applications in medical, electrical and chemical industries, among others.

Our Product Specifications

At EXOTHERM, FEP insulated high temperature wires are available in a range of specifications, such as:

| Physical, Thermal and Electrical Properties | Typical Values |

|---|---|

| Temperature | Ranging from -200° C to +200° C |

| Voltage | Ranging from 250V to 1000V |

| Size Range | 18 AWG – 40 AWG |

| Insulation Potential Strength | 2000 VAC/ min |

| Maximum Conductor Resistance | 62.5 Ω / km |

| Conductor Material | Silver-Plated or Tin-Plated Copper Conductors |

As a leading wire and cable manufacturer, our commitment to provide quality wiring solutions comes second to none. Our range of FEP insulated wires is fabricated and tested in conformance to the most rigorous quality processes.

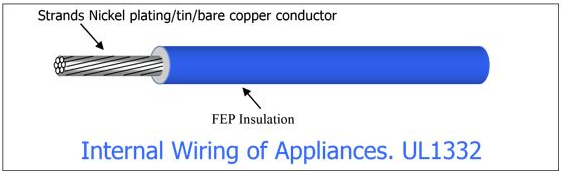

Internal wiring of appliances and electronic equipment, Suitable for immersion in gasoline; gasoline vapor; 80℃ in oil; and or 600 Volts peak for electronics use.

- Conductor material of Tinned Platted or Silver Platted copper

- Rated temperature 200

- Rated voltage 300 V (Spark voltage 3000 V)

- Flame resistance VW-1 or FT1

- RoHS Compliant

- UL 1330

- UL 1332

- UL 1591

- UL 1592

- UL 1887

Industrial Applications of FEP Insulated High Temperature Wires

FEP insulated high temperature wires possess excellent abrasion and impact resistance. Also, they exhibit excellent low temperature toughness and very low flammability. These attributes make them the reliable choice for wiring several electrical and electronic devices and systems that are subject to harsh operating conditions.

Applications of these high temperature fep wires like ul 1332, ul 1330 fep wire are endless; they are largely used for wiring:

- Military Communications Systems

- Aerospace and Aircraft Equipment and Systems

- OEM Appliances

- Nuclear Power Products

We can meet your industry specific requirements promptly as we are equipped with advanced in-house wire and cable manufacturing equipment. We assure on time product delivery, whilst meeting all product quality expectations.

View all available sizes here.