Industry Trends

Our connected world demand wires and cables that deliver a safe flow of information and power, 24 hours a day. The cable and wire industry is one of these areas inevitably affected by population and technology evolution. Environmental factors, high-speed data rise, stringent safety regulation, miniaturization and weight reduction targets, redefine performance cable productions expectations.

From home wiring for domestic appliances, to single pair Ethernet cables in the future vehicles, cable specifications are about safety as much as performance. Cable producers need to be agile enough to respond quickly to changing levels of demand while being creative in the ways they capture value. Almost considered as a conversion industry, material selection for cable coat or jacketing is then fundamental. Whether for wire insulation or cable jacketing applications, fluoro materials were for many years a preferred solution to offer against any other resin:

- Low flammability

- Low smoke emissions

- Superior dielectric properties

- High stress-crack resistance

- Extreme chemical resistance

- Extended thermal cycling capabilities

Beyond the intrinsic properties of PTFE, FEP, PFA, and ETFE, EXOTHERM expertise enables cable producers to differentiate and reduce production default for :

Automotive Oxygen sensor: EXOTHERM PTFE offered the demanded heat resistance performance required by oxygen sensors located in exhaust manifold.

Automotive Oxygen sensor: EXOTHERM PTFE offered the demanded heat resistance performance required by oxygen sensors located in exhaust manifold.

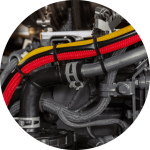

Automotive under-the-hood wires: The various wire systems enabling car engines to perform must resist to high temperature as well as frequent exposure ETFE ranges are the best solutions to meetthese requirements.

Automotive under-the-hood wires: The various wire systems enabling car engines to perform must resist to high temperature as well as frequent exposure ETFE ranges are the best solutions to meetthese requirements.

LAN Cable: LAN cables are expected to deliver increasing flow of data in the safes Properties provided by EXOTHERM FEP grades such as flame retardancy, Low dielectric constant Low tan δ are the reason why it is used for many years in LAN cable production.

LAN Cable: LAN cables are expected to deliver increasing flow of data in the safes Properties provided by EXOTHERM FEP grades such as flame retardancy, Low dielectric constant Low tan δ are the reason why it is used for many years in LAN cable production.

Coaxial cable: To ensure the precise and constant transmission required in coaxial cable, EXOTHERM grades are recommended for insulating outer sheath or jacket. EXOTHERM FEP and PFA impart low dielectric constant low tan delta, flame retardancy, and Thin line formability wanted.

Coaxial cable: To ensure the precise and constant transmission required in coaxial cable, EXOTHERM grades are recommended for insulating outer sheath or jacket. EXOTHERM FEP and PFA impart low dielectric constant low tan delta, flame retardancy, and Thin line formability wanted.

Base station: The complex cabling system of base stations antennas has the objective to support a consistent, reliable and trouble-free performance in the field EXOTHERM PTFE is the perfect solution to provide the low dielectric constant needed Low tan delta and the resistance to high temperature sought.

Base station: The complex cabling system of base stations antennas has the objective to support a consistent, reliable and trouble-free performance in the field EXOTHERM PTFE is the perfect solution to provide the low dielectric constant needed Low tan delta and the resistance to high temperature sought.

Consumer Electronics and Appliances: With resistance to heat resistance and flame retardancy properties, EXOTHERM PFA and FEP enables appliance and consumer goods producer to ensure performance safety, and extended service range.

Consumer Electronics and Appliances: With resistance to heat resistance and flame retardancy properties, EXOTHERM PFA and FEP enables appliance and consumer goods producer to ensure performance safety, and extended service range.