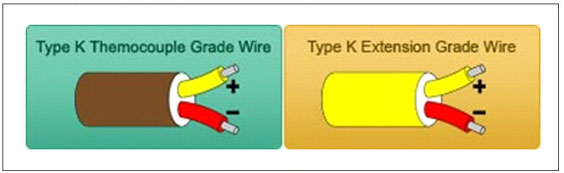

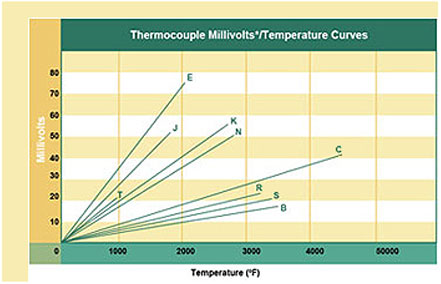

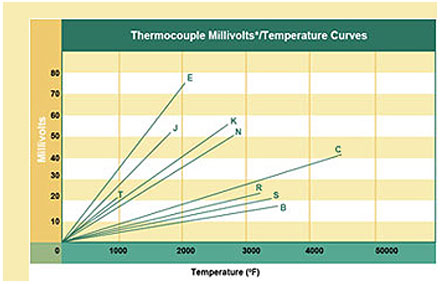

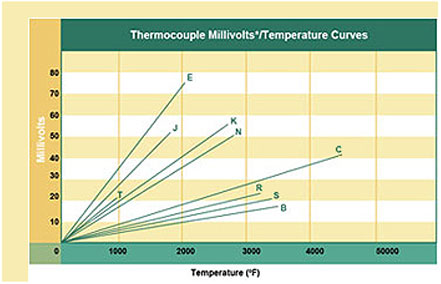

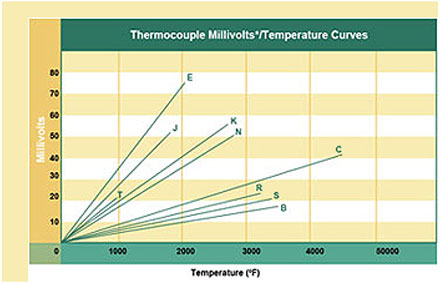

There are multiple types and grades of thermocouple wire. Each type of thermocouple wire has a specific combination of metal alloys. This combination is what defines the type of thermocouple. For example, a type K thermocouple is made when a wire of Nickel-Chromium is welded to a wire of Nickel-Alumel. The grade of the wire is dependent not only on the combination of alloys used, but also on the purity of those alloys. For a full list of thermocouple types and corresponding thermocouple wires, see our thermocouples types page

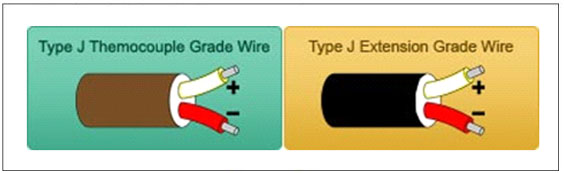

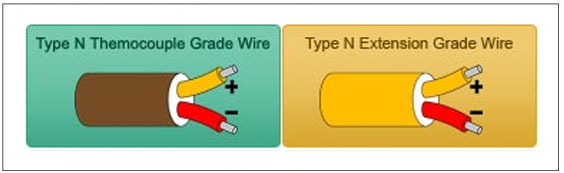

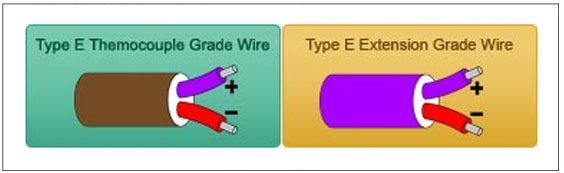

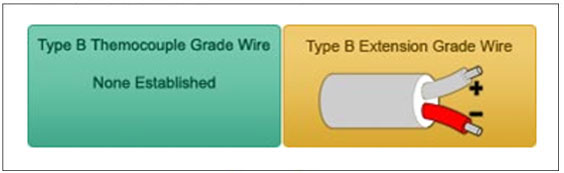

Thermocouple Grade Wire vs. Extension Grade Wire

Thermocouple grade wire is used to manufacture thermocouple probes. Thermocouple grade wire is normally used for the junction and inside the stem sheath. This is because the thermocouple grade wire has a accuracy specification than extension grade wire.

Extension grade wire is a less expensive, lower grade wire. It is used to extend from the thermocouple probe to the control system or digital display. Extension grade wire is more economical due to the length requirements. Also, it is not in the process itself and does not play as critical a role nor does it experience the temperature extremes & temperature cycling.

In many industrial applications a sensor is located in a process pipe far away from the control room. This means a wire must be run a considerable distance back to the control room to get the temperature reading. Using more expensive thermocouple grade wire to accomplish this is unnecessary. Extension grade wire will do the job.

Special Limits of Error (SLE) vs. Standard Limits of Error

Standard limits of Error: These thermocouples use standard “thermocouple grade” wire and make up the great majority of sensors.

Special Limits of Error: These thermocouples are made with a higher grade of thermocouple wire that is purer than standard wire, which increases their accuracy. They are more expensive than standard thermocouples.

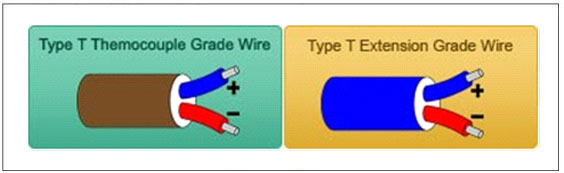

Thermocouple Wire - Color Codes

A thermocouple can be identified by the color of its wire insulation. For example, in the United States a type J thermocouple has one red wire and one white wire, typically with a brown over jacket. A type J extension grade wire also has one red wire and one white wire, but it has a black over jacket. As a general rule the red wire of a thermocouple or extension wire is negative and the positive wire is color coded according to the type of thermocouple. Different countries use different color codes.

Visit our Thermocouple Color Codes page for a complete list.

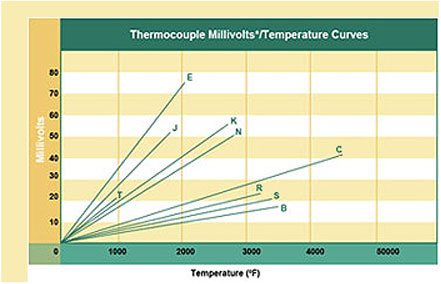

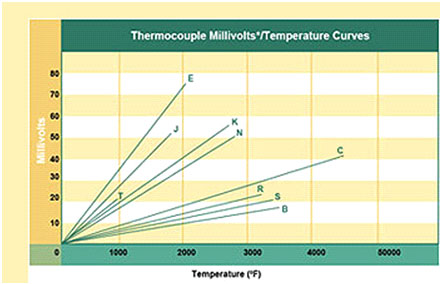

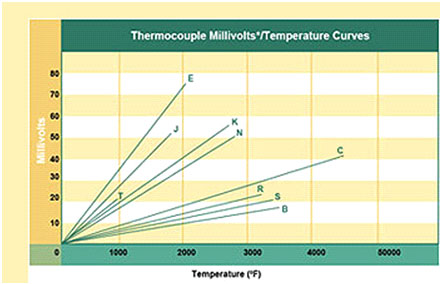

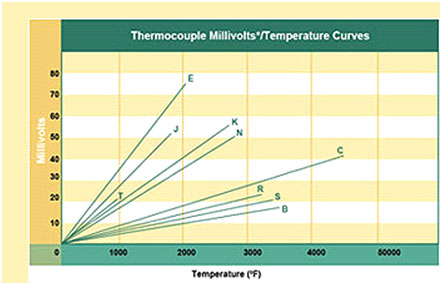

Types of Thermocouple

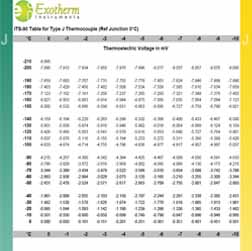

The type J is also very common. It has a smaller temperature range and a shorter lifespan at higher temperatures than the Type K. It is equivalent to the Type K in terms of expense and reliability.

- Thermocouple grade wire, -346 to 1,400F (-210 to 760C)

- Extension wire, 32 to 392F (0 to 200C)

- Standard: +/- 2.2C or +/- .75%

- Special Limits of Error: +/- 1.1C or 0.4%

- The Type J Is Well Suited To Oxidizing Atmospheres

The type K is the most common type of thermocouple. It’s inexpensive, accurate, reliable, and has a wide temperature range. The type K is commonly found in nuclear applications because of its relative radiation hardness. Maximum continuous temperature is around 1,100C.

- Thermocouple grade wire, –454 to 2,300F (–270 to 1260C)

- Extension wire, 32 to 392F (0 to 200C)

- Standard: +/- 2.2C or +/- .75%

- Special Limits of Error: +/- 1.1C or 0.4%

- The Type K Is Well Suited To Oxidizing Atmospheres

The Type T is a very stable thermocouple and is often used in extremely low temperature applications such as cryogenics or ultra low freezers. It is found in other laboratory environments as well. The type T has excellent repeatability between –380F to 392F (–200C to 200C).

- Thermocouple grade wire, -454 to 700F (-270 to 370C)

- Extension wire, 32 to 392F (0 to 200C)

- Standard: +/- 1.0C or +/- .75%

- Special Limits of Error: +/- 0.5C or 0.4%

- The Type T Is Well Suited To Oxidizing Atmospheres

The Type N shares the same accuracy and temperature limits as the Type K. The type N is slightly more expensive. The type N has better repeatability between 572F to 932F (300C to 500C) compared to the type K.

- Maximum continuous operating temperature: up to 2,300F (1,260C)

- Short term use: 2,336F (1,280C)

- Thermocouple grade wire, -454 to 2300F (-270 to 1,260C)

- Extension wire, 32 to 392F (0 to 200C)

- Standard: +/- 2.2C or +/- .75%

- Special Limits of Error: +/- 1.1C or 0.4%

- The type N holds up better to oxidation at high temperatures when compared to the type K.

The Type E has a stronger signal & higher accuracy than the Type K or Type J at moderate temperature ranges of 1,000F and lower. The type E is also more stable than the type K, which adds to its accuracy.

- Thermocouple grade wire, -454 to 1600F (-270 to 870C)

- Extension wire, 32 to 392F (0 to 200C)

- Standard: +/- 1.7C or +/- 0.5%

- Special Limits of Error: +/- 1.0C or 0.4%

- In oxiding or inert atmospheres the operating range is roughly –418F to 1,652F (–250C to 900C).

The Type B thermocouple is used in extremely high temperature applications. It has the highest temperature limit of all of the thermocouples listed above. It maintains a high level of accuracy and stability at very high temperatures. The type B has a lower output than the other noble metals (type R & type S) at temperatures below 1,112F (600C).

- Thermocouple grade wire, 32 to 3100F (0 to 1700C)

- Extension wire, 32 to 212F (0 to 100C)

- Standard: +/- 0.5%

- Special Limits of Error: +/- 0.25%

- In oxiding or inert atmospheres the operating range is roughly –418F to 1,652F (–250C to 900C).

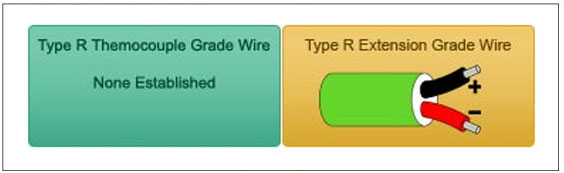

The Type R is used in very high temperature applications. It has a higher percentage of Rhodium than the Type S, which makes it more expensive. The Type R is very similar to the Type S in terms of performance. It is sometimes used in lower temperature applications because of its high accuracy and stability. Type R has a slightly higher output and improved stability over the type S.

- Thermocouple grade wire, -58 to 2700F (-50 to 1480C)

- Extension wire, 32 to 392F (0 to 200C)

- Standard: +/- 1.5C or +/- .25%

- Special Limits of Error: +/- 0.6C or 0.1%

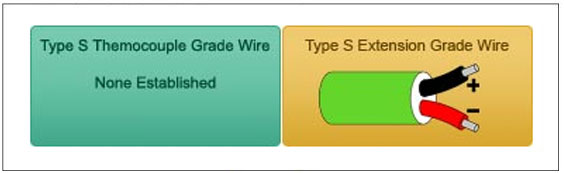

The Type S is used in very high temperature applications. It is commonly found in the BioTech and Pharmaceutical industries. It is sometimes used in lower temperature applications because of its high accuracy and stability. The type S is often used with a ceramic protection tube.

- Maximum continuous operating temperature: up to 2,912F (1600C)

- Short term use: up to 3,092F (1,700C)

- Thermocouple grade wire, -58 to 2700F (-50 to 1480C)

- Extension wire, 32 to 392F (0 to 200C)

- Standard: +/- 1.5C or +/- .25%

- Special Limits of Error: +/- 0.6C or 0.1%

- The Type S can be used in inert and oxidizing atmospheres up to 2,912F (1600C) continuously and up 3,092F (1,700C) for short term use.